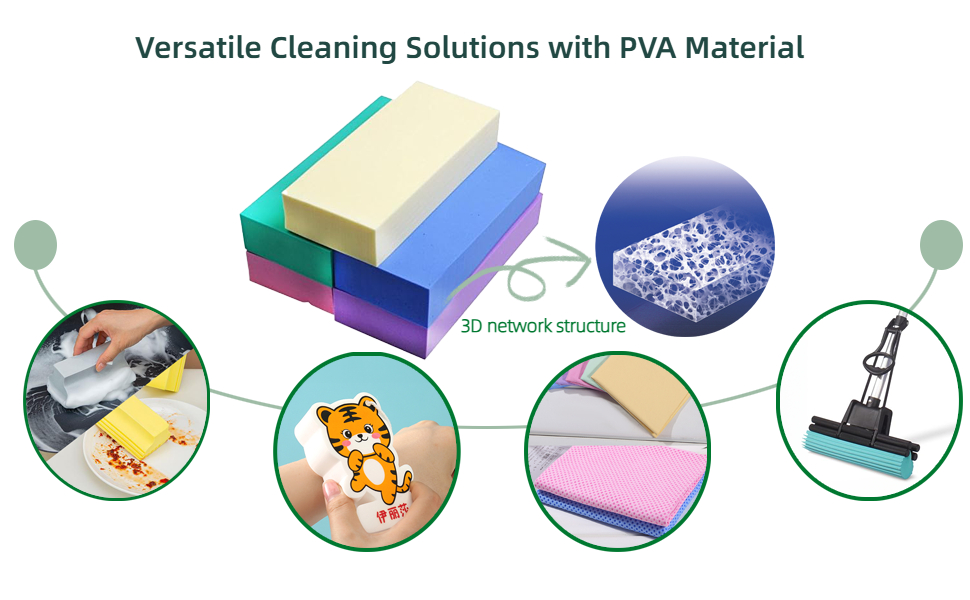

PVA Sponge

Composition:

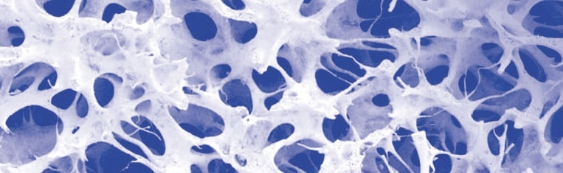

PVA sponge, made from Polyvinyl Alcohol, is an open-celled, highly absorbent material designed for maximum durability and versatility. With up to 90% of its volume being hollow, its unique three-dimensional network structure enhances its superior absorbency, making it capable of holding up to 12 times its dry weight in water.

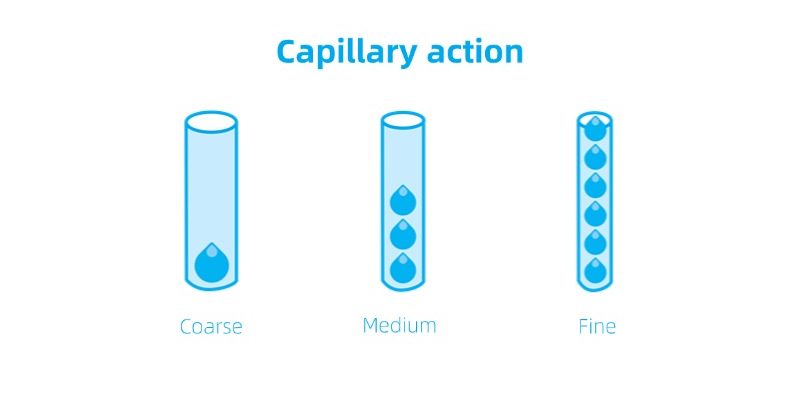

The sponge features customizable options in terms of colors, shapes, and pore sizes to meet various application needs. Its hydrophilic nature ensures excellent water-wicking capabilities, while its high tensile strength and superior chemical resistance make it suitable for a wide range of demanding applications.

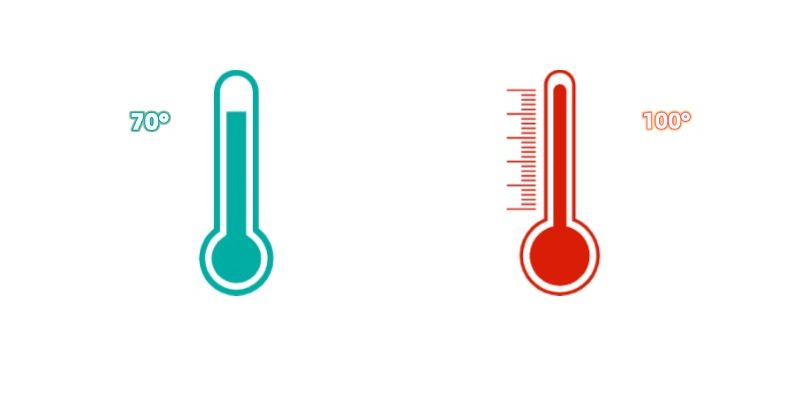

Additionally, PVA sponge demonstrates excellent temperature tolerance, withstanding up to 70°C when hydrated and approximately 100°C when dry. These properties, combined with its advanced manufacturing process, ensure exceptional performance in both industrial and consumer settings.

What are the benefits of PVA Sponge?

PVA sponge is hydrophilic and can holdup to 12 times its dry weight in water.

Cell size can be varied depending onthe required capillary action.

The wet sponge withstands temperaturesnearing 70’C and the dry about 100’C.

Customizable Shapes and Colors for All Applications:

PVA sponges can be tailored to meet diverse requirements, including custom shapes, colors, and styles. From block sponges, bath scrubbers, and absorbent rollers to high-precision absorbent sheets, we offer customizable options to suit specific cleaning or industrial tasks. Additionally, PVA absorbent sheets are available for further processing, giving customers the flexibility to design their own products.

Yellow

Blue

Green

Purple

Pink

Physical Properties of PVA Sponge:

Property | Parameters |

|---|---|

| Material | Polyvinyl formal resin |

| Hydrophilic or hydrophobic | Hydrophilic |

| Pore making method | Particle removal method |

| Type of pores | Labyrinthal and continuous |

| Porosity (%) | 85~95 |

| Average pore size (μ) | 60~2000 |

| Apparent density (g/cm²) | 0.07~0.12 |

| 30% compressive stress (g/cm²) | 20~120 |

| Tensile strength (kg/cm²) | 2~9 |

| Tensile elongation (%) | 100~300 |

| Abrasion resistance (times) | 1000~2000 |

| Property | Parameters |

|---|---|

| Water absorption rate (wt.%) | 500~1200 |

| Water absorption speed (sec/cm) | 2~15 |

| Condition when dry | Hard |

| Maximum allowable temperature (°C) | Wet 60 Dry 120 |

| Melting point or decomposition point (°C) | 266 (※JIS method) |

| Weather resistance | No apparent change with 1000hrs irradiation by a fade-o-meter |

| Acid resistance | Dissolved by very strong acids |

| Alkali resistance | Hardened by strong alkalis |

| Solvent resistance | Weakened with chloroform and dichloroethane |

| Conditions when burned | No noxious gas |

Manufacturing

How Is PVA Sponge Manufactured?

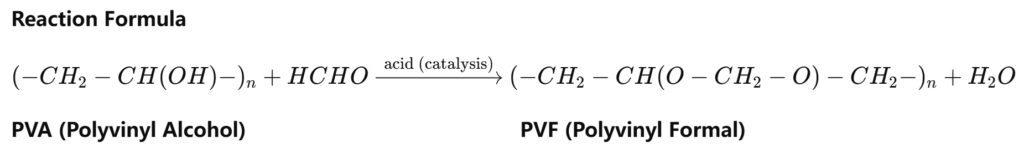

a. PVA Sponge has a porous structure made from water soluble PVA acetalized with an acid catalyst. The finished product becomes PolyVinyl Formal – often referred to as “PVA Sponge”. Please refer to the Reaction Formula chart.

b. During the acetalizing process, the pore forming agent or method (starch or air) is added. After a water soluble porous structure is made, the agent (starch) is extracted. In the case of air pore forming, there is no need to remove any additional material.

c. The finished product has a three-dimensional, interconnected porous structure. Refer to the micrograph for a 3D view of the pore structure. After extensive washing and rinsing of the finished product, it is packed and shipped.

Chemical Reaction Formula for PVA to PVF Conversion

Magnified picture of sponge structure

PVA Sponge has interconnected cells resembling a natural sea sponge