Abrasive Pads

Composition:

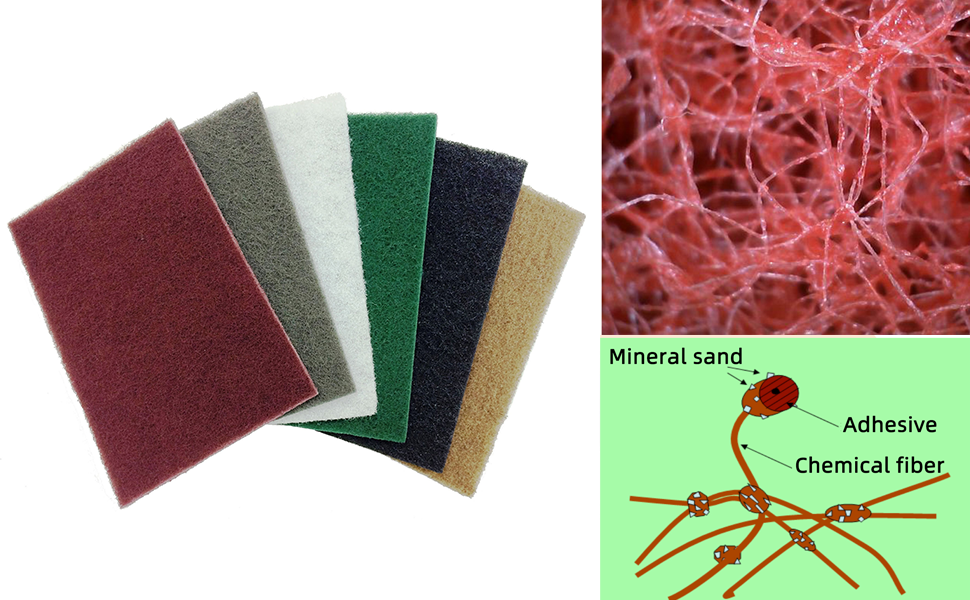

Abrasive pads are versatile tools designed for surface treatment, featuring abrasive grains bonded to backing materials such as cloth, film, paper, or non-woven substrates. Typically shaped as squares or rectangles, they are available in various forms including hand pads, block brushes, tufts, and paint pads. Hand pads, often round or contoured, are thicker than abrasive sheets and may include handles or loops to enhance usability and grip during application.

Block brushes are constructed with a sturdy core or backing and fitted with tufts—clusters of bristles, filaments, or wires—arranged to effectively remove dirt, rust, or debris. Paint pads, designed to be absorbent, are particularly useful for creating textures or applying coatings in hard-to-reach areas. The adaptability and functionality of abrasive pads make them essential for cleaning, polishing, and surface preparation in diverse applications.

Abrasive Pads: Grain Types and Grit Sizes

Beyond width and length, abrasive pads vary significantly in their abrasive grain types. Options include materials such as aggregate, aluminum oxide, boron carbide, ceramic, cork, synthetic diamond, emery or crocus, silicon carbide (SiC), cubic boron nitride (CBN), tungsten carbide, and alumina-zirconia. Among these, synthetic diamond and CBN are classified as superabrasives, created through high-temperature, high-pressure processes using an anvil press.

When selecting abrasive pads, grain or grit size is another crucial factor to consider. Grit sizes are commonly determined by standards such as ANSI, FEPA, JIS, or proprietary grading systems. These standards establish grit sizes by specifying upper and lower size limits within a distribution. ANSI and CAMI are widely recognized standards in the U.S., FEPA is used across Europe, and JIS is the primary grit-size grading standard in Japan.

Grit Size (Range) | Characteristics | Applications | Color (Typical) | Evaluation | Industry | FEPA Standard (P Range) | ANSI Standard (Mesh) | JIS Standard (Mesh) |

|---|---|---|---|---|---|---|---|---|

| 24-60 (Coarse) | Large abrasive grains, high material removal rate, rough surface finish. | Rust removal, heavy-duty cleaning, weld seam grinding. | Dark Brown or Red | High efficiency for rough jobs, but may damage delicate surfaces. | Heavy industry, construction | P24-P60 | 24-60 | #24-#60 |

| 80-120 (Medium) | Moderate abrasive grains, balance between material removal and smooth finish. | General-purpose cleaning, light deburring, surface preparation. | Maroon or Green | Versatile, suitable for most applications, moderate aggressiveness. | Automotive, general manufacturing | P80-P120 | 80-120 | #80-#120 |

| 150-240 (Fine) | Small abrasive grains, fine surface finish, minimal material removal. | Surface smoothing, finishing, and light polishing tasks. | Gray or Blue | Produces smooth finishes, good for detailed work. | Furniture making, home improvement | P150-P240 | 150-240 | #150-#240 |

| 320-600 (Ultra-Fine) | Very small abrasive grains, creates ultra-smooth surfaces. | Final polishing, surface refinement, preparing for high-gloss finishes. | Light Gray | Exceptional for final polishing, minimal surface damage. | Aerospace, high-end manufacturing | P320-P600 | 320-600 | #320-#600 |

| 800+ (Micro-Fine) | Extremely fine abrasive grains, suitable for precision polishing. | Mirror finishing, high-precision polishing for optics, jewelry. | White or Transparent | Precision tool, perfect for achieving mirror-like finishes. | Optics, luxury goods | P800+ | 800+ | #800+ |

Our Custom Abrasive Pad Solutions: Available Types

Belt

Brick

Cord

Disc

Flap Disc

Roll

Shank-Mount Pad

Sheet

Sponge

Stick

Manufacturing

We specialize in manufacturing a wide variety of abrasive pads and sponges, including customizable options like belts, discs, sheets, rolls, and more. By utilizing advanced technologies and high-quality materials such as aluminum oxide, silicon carbide, ceramic, and premium sponge bases, we ensure durable, high-performance products for diverse applications. Our process emphasizes precision, flexibility, and eco-friendly practices, catering to unique customer requirements with efficiency and quality.