Cellulose Sponge

Composition:

Cellulose sponges are made from natural wood pulp materials. To provide our customers with the highest quality products, we source the best raw materials available. We partner with farms that operate under strict environmental regulations and maintain a rigorous selection process for our suppliers, conducting regular audits to ensure compliance.

Our cellulose sponges are manufactured in China, with our primary factory located in Suzhou. The facility is certified under ISO 9001 (Quality Management) and ISO 14001 (Environmental Management). From sourcing to delivery, we oversee every stage of the manufacturing process.

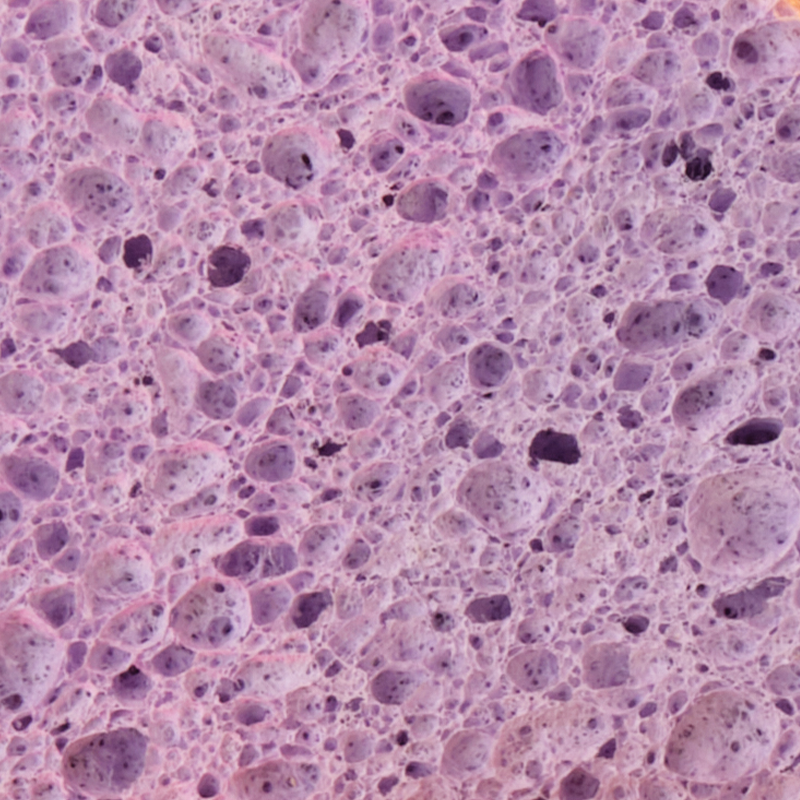

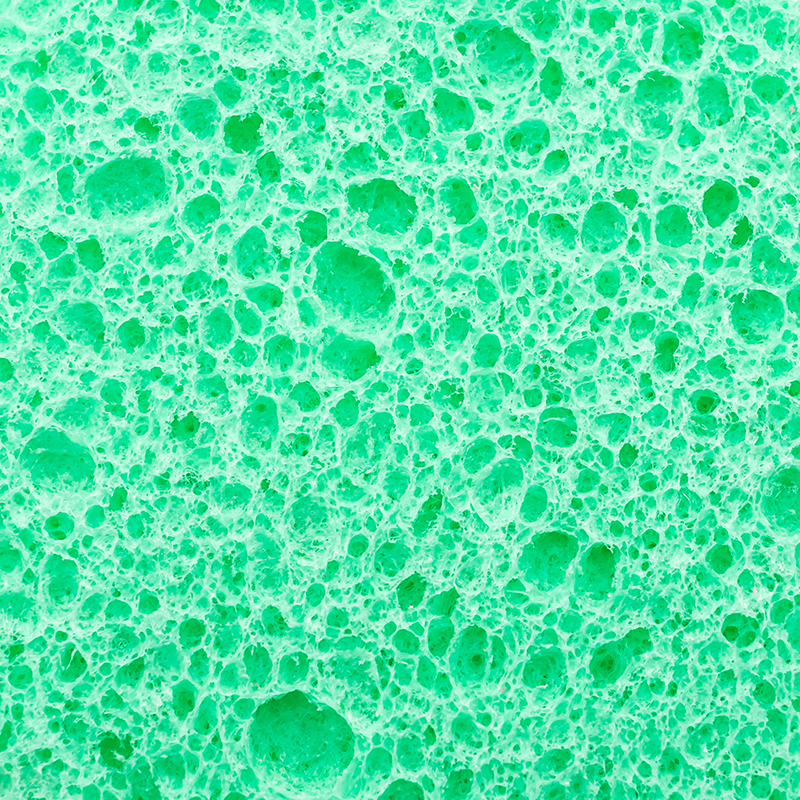

Our production process is highly sophisticated and automated. During production, various colors and pore sizes can be customized. The material can be produced in either a dry or wet state. Initially, the sponges are manufactured in bulk blocks and are then customized through cutting, punching, drilling, or slotting to meet customer specifications.

Vibrant Color Options for Every Cleaning Need

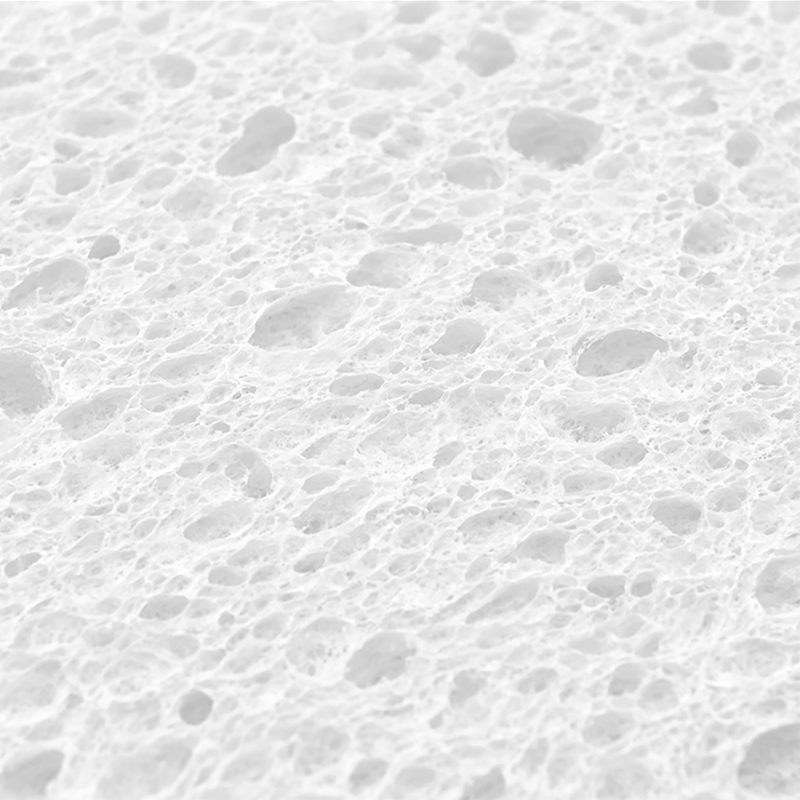

Fluorescent White

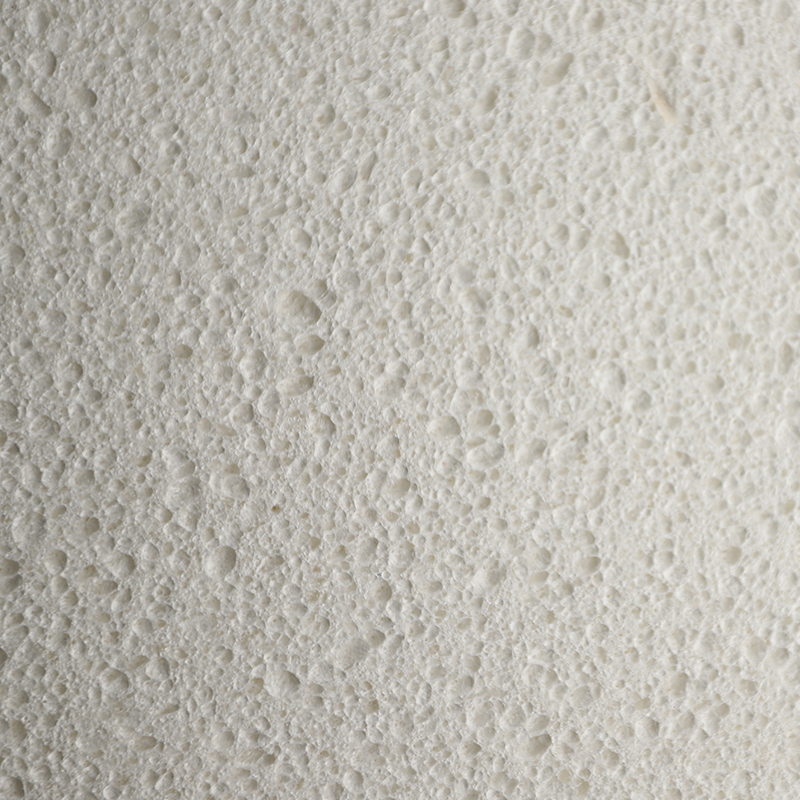

Natural White

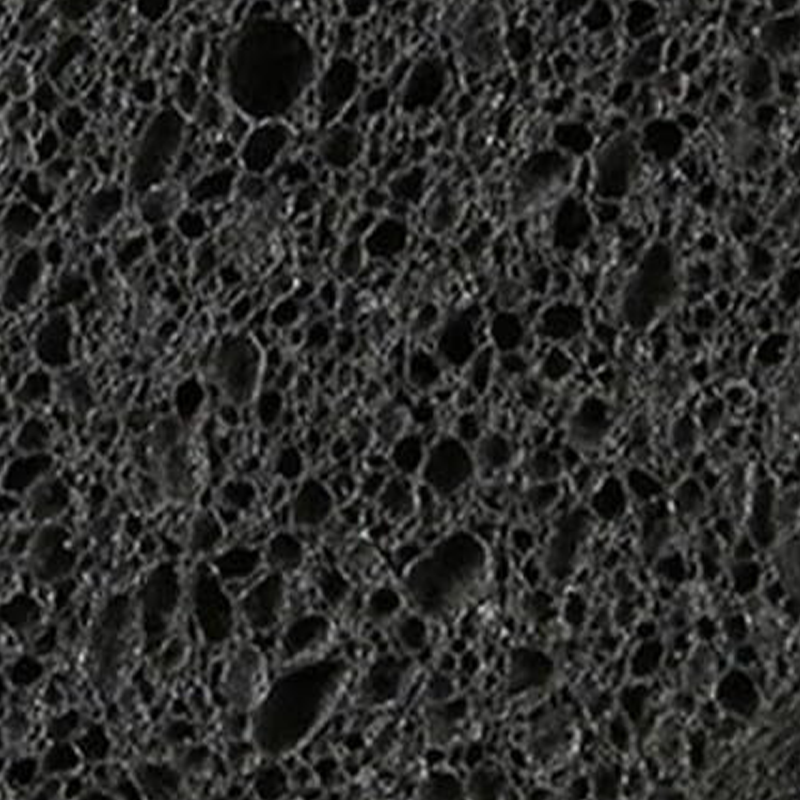

Grey

Fluorescent White

Violet

Blue

Buff

Yellow

Green

Pink

Characteristics

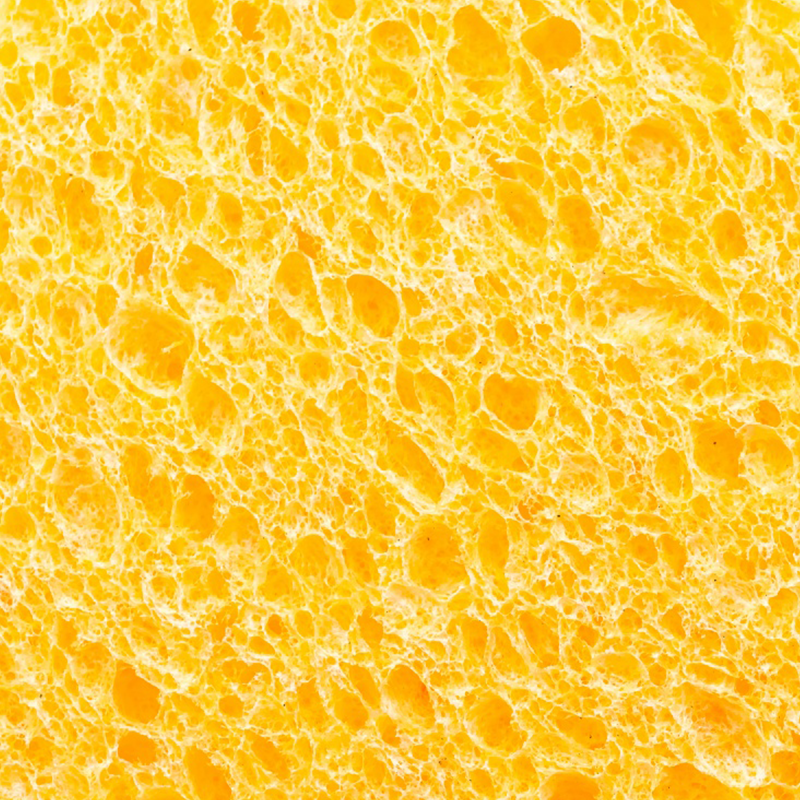

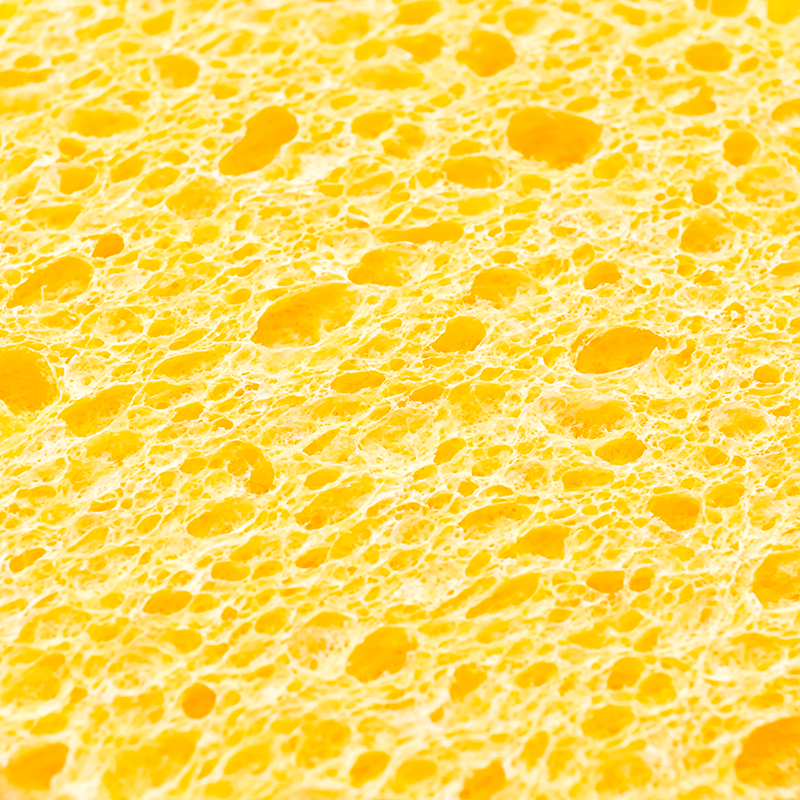

High Liquid Absorption and Retention Capacity

The unique porous structure provides a large surface area with an open-cell network. As a result, natural cellulose sponges can absorb up to 20 times their dry weight in water, retaining it within their pore structure. This property also applies to other liquids such as motor oil, petroleum, gasoline, and diluted acids like formic acid or nitric acid. The sponge continues to absorb liquids until it reaches its maximum capacity.

Compressibility

Cellulose sponges can be compressed while retaining 100% of their original properties. They expand to their full size only upon contact with water. Compression is possible only when dry, as the material exhibits elasticity when wet.

Tensile Strength

These sponges rank among the most durable on the market. Their tensile strength is routinely tested during production, offering a significant advantage over cotton cloths, nonwoven fabrics, and paper towels.

Cleaning Performance

For decades, the cleaning performance of cellulose sponges has been widely recognized. Their unique outer skin layer provides a compact and robust structure.

Biodegradability

Cellulose sponge materials are 100% biodegradable.

Biocompatibility

In their dry state, these sponges are proven to be hypoallergenic. Bleach-free sponges can also be produced. These sponges are frequently used in Class II and Class III medical devices by customers.

Chemical Resistance

In moist conditions, natural cellulose sponges exhibit outstanding electrical conductivity, a feature often utilized in electrotherapy applications.

Flammability and Thermal Resistance

Cellulose sponge material is flammable, but the rate of combustion varies depending on the liquids it has absorbed. Thermal analyses indicate that cellulose ignites at temperatures above 300°C.

Filtration Capabilities

Cellulose sponges can filter certain impurities from gases and liquids, depending on the material’s properties.

Sterilization Compatibility

These sponges can be sterilized using standard methods such as high-temperature steam or specialized sterilizing gases, making them highly suitable for maintaining hygiene.

Washability

Cellulose sponge materials can be machine washed with detergents at temperatures up to 95°C.

Storage and Transport

In compressed form, cellulose sponges are highly suitable for storage and transportation. Their lightweight and compact nature significantly reduce shipping and storage costs.

Manufacturing

The finished products we deliver fully embody the exceptional expertise demonstrated throughout the manufacturing process. We understand that our clients’ projects require a wide range of manufacturing and processing techniques, along with the expertise and capability to advance these processes to meet their objectives. Moreover, we collaborate closely with professionals in specialized manufacturing fields to ensure goals are achieved and desired results are delivered.

With high-quality materials as the foundation, our advanced manufacturing capabilities drive the realization of innovative and high-performance industrial products.

Compressed viscose sponge materials offer versatile benefits, particularly in industrial applications like sealing and waterproofing. Compression not only ensures functional reliability but also reduces storage and logistics costs. Industrial processes typically use equipment with pressures up to 250 tons for sponge compression.

Also called expanding, absorbent, or pop-up sponges, these are made by compressing cellulose sponges under high pressure and temperature. They expand to their original size upon contact with liquid, regaining properties of uncompressed sponges, and can absorb liquids up to 20 times their weight.

Special Features

- Expands on contact with liquids

- Low transport and storage volume

- Suitable for both manual and mechanical use

- Can be specially adapted to their later application

- Also available with stabilizing external skin

Production Possibilities

- Available in different colours and printable

- Different expanding-heights

- Square, round, oval or individually-shaped cuts

- Drill holes and punched holes to your specifications

- Different sizes up to around 850 x 800mm

Possible Geometrical Designs

- Circle and Oval

- Rectangular and Square

- Free shapes with a cutting line

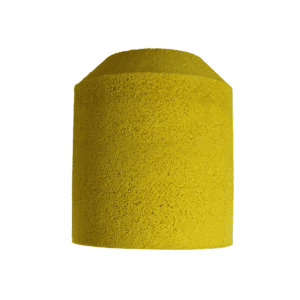

- Cylinders

- Cube and Cuboid

Selection of Punching Methods Based on Design and Order Volume

- Receding Head Press (most powerful type, perfect for big shapes or high order volumes)

- Fast Belt Press (suitable for humid cellulose sponge material and medium order volumes)

- Manual Press (perfect for proto-typing or tailor made small batches)

Die-cutting is a manufacturing process that uses a press and punching tool to shape or cut materials. We evaluate designs and materials to optimize tools, calculate costs, and improve production efficiency.

We produce various viscose sponges by cutting raw material blocks into custom shapes. Depending on the quantity needed, sponge blocks are cut horizontally or vertically using specialized band saws to ensure optimal production.

Vertical cut Horizontal cut

Advantages for this type of production is the ability to match the customer’s specifications and saving tool costs.

- Rectangular Solid

- Cube

Possible Geometrical Designs

- Rectangular sizes up to approx. 1,200 x 920 x 100mm

- Even the smallest sizes are possible

- Rectangular, square, as a cube

- Dry or humid sponge material

- Drill holes or slots in the required positions and sizes

- Shaping and sizes to your individual requirements

Drilling

For certain applications, sponges require one or more drill holes. These holes serve as holders in specific equipment, such as medical systems, or allow liquids to flow freely for processes like polishing or oiling. Depending on the design and application, holes can be made manually or with automated machines. The shape and size of the holes are determined by the sponge’s design, size, and porosity. We work to find the best solution for your project.

Slotting

We provide sponge slotting services using small horizontal saws to create pouches or bags. These are suitable for various applications, including electrotherapy systems.

Many industrial customers require custom 3D sponge shapes, such as cubes or cylinders.

To meet these needs, we use advanced methods like water cutting.

This technique uses pure water pumped through a cutting head. While simple to operate, it involves sophisticated material and design technologies. A 3D cutting head is essential for precise shaping.

We select the best technology for each application, leveraging our extensive network of experienced partners.

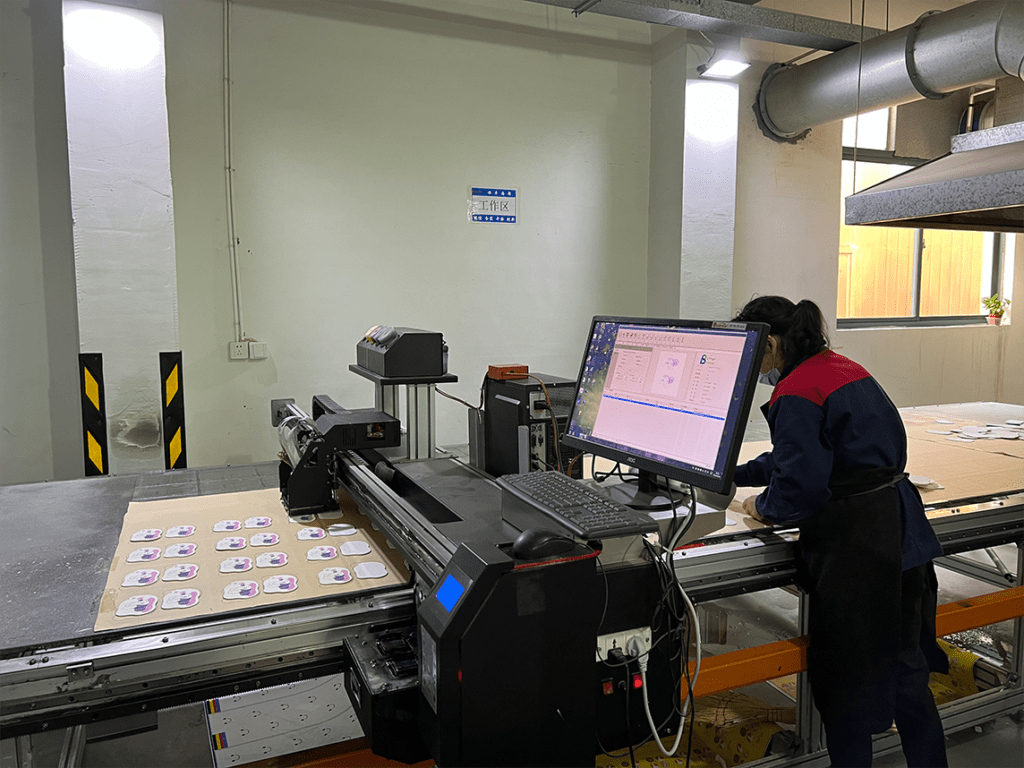

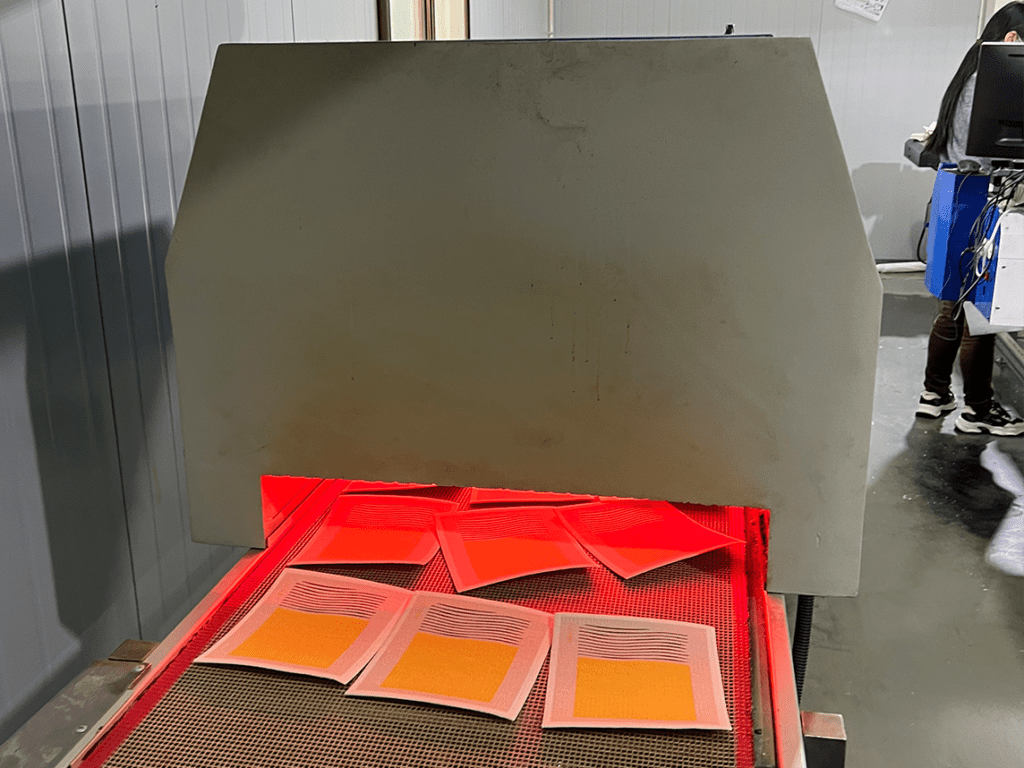

For promotional or advertising purposes, printing on cellulose sponge products is an excellent option. It adds a personalized touch to the product while conveying the desired message or brand identity.

Custom Printing Services

Cellulose sponges can be customized with clear and durable prints that remain intact during use. Whether it’s a brand logo, tagline, or other design elements, we tailor the printing to meet your specific needs.

We recommend discussing your design ideas with our team during the planning stage to ensure the final print matches your expectations. Our experts are here to support your creativity and help achieve outstanding design and printing results.

In addition to our products, we also offer a range of additional services to meet your needs. Beyond supplying raw materials or cut products, we provide packaging solutions for these items. Raw materials are typically packed in cartons with foil liners, while cut products can be packaged either individually or in bulk. Various packaging options are available upon request.

List of packaging and service solutions:

- Manual or automatic individual packaging (flow pack)

- Neutral or printed wrappings

- Bundling

- Labelling

- Logistic services and drop shipments

We aim to tailor our services to suit your specific requirements, ensuring convenience and flexibility in how your products are delivered.

We have been a trusted partner in producing high-quality and customizable viscose sponges for over 15 years. Our viscose material is ideal for surface technology as well as manual and industrial cleaning of components and surfaces. This soft yet durable material is suitable for nearly all surfaces, including plastic, ceramic, glass, and metal. With open-cell liquid absorption, chemical and acid resistance, and excellent cleaning performance, these sponges are versatile for both manual and mechanical applications.

Our dedicated team of experts is committed to supporting innovative products throughout their key development stages and lifecycle. From the initial concept to implementation and practical use, we are here to assist every step of the way.

Your application, our solution. We provide advice and support for your ideas, projects, and plans.