Introduction to Compressed Cellulose Sponge Sheets Compressed cellulose sponge sheets, a key product in the cleaning and hygiene sectors, have seen a surge in demand due to their efficacy and eco-friendliness. The cellulose sponge manufacturing process plays a crucial role in determining the quality of these sheets. These sponges are highly absorbent, durable, and are derived from natural cellulose fibers, typically from wood pulp. A key factor in their appeal is their ability to be compressed, which makes them easy to store and transport. This has led to a growing market, with the global demand for compressed cellulose sponge sheets expected to rise substantially in the coming years. Businesses seeking these sponge sheets should prioritize suppliers who demonstrate transparency in their cellulose sponge manufacturing process, ensuring the products are of the highest quality and sustainability.

Understanding the Cellulose Sponge Manufacturing Process The cellulose sponge manufacturing process is intricate and plays a vital role in the final product’s quality. It begins with the preparation of a cellulose solution, typically derived from wood pulp. This solution is then mixed with softeners and other additives to create a malleable mixture. The key to high-quality compressed cellulose sponge sheets lies in the precise control of this mixture’s density and porosity. The mixture is then poured into molds and undergoes a process of heating and compression. This stage is crucial as it determines the sponge’s final texture and absorbency. Quality control measures are essential at each stage to ensure the consistency and reliability of the final product. The most advanced cellulose sponge manufacturing processes incorporate eco-friendly practices, like using sustainable wood sources and minimizing chemical waste.

Key Factors in Sourcing Quality Compressed Sponge Sheets When sourcing compressed cellulose sponge sheets, several key factors must be considered to ensure product quality. These include the density of the sponge, which affects its absorbency and durability; the purity of the cellulose used, as higher purity results in a more effective sponge; and the uniformity of pore size throughout the sponge sheet. Prospective buyers should also consider the supplier’s track record in the market, their adherence to environmental standards in the cellulose sponge manufacturing process, and their ability to provide consistent quality over time. It’s also vital to consider the supplier’s capacity to customize sponge sheets according to specific needs, such as size, shape, and additional functional properties. A thorough evaluation of these factors will lead to a more informed sourcing decision, ensuring that the compressed cellulose sponge sheets meet the required standards for various applications.

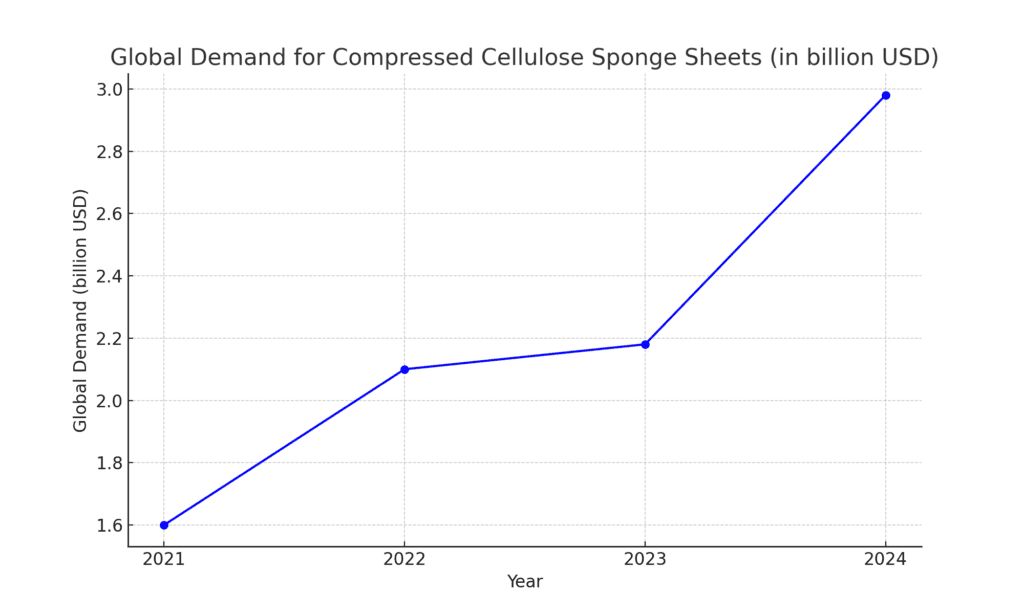

Data Table Display: Global Demand for Compressed Cellulose Sponge Sheets

Year Global Demand (in billion USD) 2021 1.6 2022 2.1 2023 2.18 2024 2.98 (Projected) 2025 N/A

1Key Factors in Sourcing Quality Compressed Sponge Sheets Sourcing quality compressed cellulose sponge sheets demands a comprehensive understanding of the cellulose sponge manufacturing process. Key factors include the density and absorbency of the sponge sheets, which are directly influenced by the manufacturing process. Density determines the sponge’s strength and longevity, while absorbency measures its effectiveness in cleaning applications. Suppliers should provide detailed specifications, including density and absorbency metrics, to ensure that the compressed cellulose sponge sheets meet industry standards. Additionally, the cellulose sponge manufacturing process should prioritize environmental sustainability, using renewable resources and minimizing waste. Transparency in sourcing materials and manufacturing methods is crucial for suppliers to build trust with customers. Regular audits and certifications can also provide assurance about the quality and sustainability of the compressed cellulose sponge sheets.

Evaluating Suppliers and Manufacturing Standards When evaluating suppliers of compressed cellulose sponge sheets, it’s essential to assess their adherence to high manufacturing standards. The cellulose sponge manufacturing process should align with international quality and environmental regulations. Suppliers should be able to demonstrate compliance with these standards through certifications like ISO or EcoLabel. Additionally, the longevity and reputation of a supplier in the market can be a testament to their commitment to quality. It’s also beneficial to visit the cellulose sponge manufacturing facilities to observe the production process firsthand. This can provide insights into the operational efficiency, quality control measures, and the overall reliability of the supplier in producing high-quality compressed cellulose sponge sheets.

The Role of Sustainability in Sponge Sheet Production Sustainability is becoming increasingly crucial in the cellulose sponge manufacturing process. Consumers and businesses are more aware of their environmental impact and prefer products like compressed cellulose sponge sheets that are made sustainably. A sustainable manufacturing process involves using renewable resources, such as eco-friendly wood pulp, and minimizing the use of harmful chemicals. It also encompasses efficient waste management and recycling practices. Suppliers of compressed cellulose sponge sheets who prioritize sustainability not only contribute positively to the environment but also cater to the growing market demand for eco-friendly products. This commitment to sustainability can be a significant differentiator in the market and can influence the decision-making process of consumers and businesses alike.

Data Table: Sustainability Metrics in Sponge Sheet Production

| Sustainability Factor | Description |

|---|---|

| Renewable Resources | Usage of eco-friendly wood pulp in the manufacturing process |

| Waste Management | Efficient practices in recycling and waste reduction |

| Chemical Use | Minimal use of harmful chemicals |

| Certifications | Possession of environmental and quality certifications like ISO, EcoLabel |

In these expanded paragraphs, the focus is on the critical aspects of sourcing quality compressed cellulose sponge sheets, evaluating suppliers, and the importance of sustainability in the cellulose sponge manufacturing process. The data table provides a concise overview of sustainability metrics that are integral to the production of eco-friendly sponge sheets.

6、Market Trends and Consumer Preferences

In the evolving landscape of the cellulose sponge market, particularly concerning compressed cellulose sponge sheets, staying abreast of market trends and consumer preferences is crucial. The current trend shows a growing inclination towards eco-friendly and sustainable products, impacting the cellulose sponge manufacturing process significantly. Consumers are increasingly aware of the environmental impact of their purchases, leading to a higher demand for compressed cellulose sponge sheets made through sustainable practices.

The cellulose sponge manufacturing process has adapted to these changing consumer preferences by incorporating eco-friendly materials and methods. This shift is not only a response to consumer demand but also a move towards more responsible manufacturing practices. The use of renewable resources and reduced chemical waste in the cellulose sponge manufacturing process is becoming more prevalent.

Furthermore, advancements in technology have enabled the production of higher-quality compressed cellulose sponge sheets. These technological improvements are reflected in the enhanced durability, absorbency, and versatility of the sponge sheets, making them suitable for a wider range of applications. The integration of innovative techniques in the cellulose sponge manufacturing process has led to the development of products that cater to specific consumer needs, such as hypoallergenic or antibacterial sponge sheets.

Data Table: Consumer Trends in Compressed Cellulose Sponge Sheets

| Year | Trend | Description |

|---|---|---|

| 2021 | Eco-Friendly | Increased demand for environmentally sustainable products |

| 2022 | Technological Advancements | Introduction of advanced manufacturing techniques |

| 2023 | Specialized Products | Rising popularity of hypoallergenic and antibacterial sponges |

| 2024 | Consumer Awareness | Growth in consumer awareness about sustainable products |

In this expanded paragraph, the focus is on the latest trends in the market for compressed cellulose sponge sheets and how the cellulose sponge manufacturing process has evolved to meet changing consumer preferences. The data table provides a snapshot of these trends over recent years, highlighting the industry’s response to consumer demands for sustainability, technological advancement, and specialized products.

7. FAQ

Q1: What defines the quality of cellulose sponge sheets? A1: Quality is determined by material purity, absorbency, and manufacturing standards.

Q2: How important is sustainability in sourcing? A2: Very. Sustainable practices ensure quality and meet increasing consumer demand for eco-friendly products.

8. Conclusion

Sourcing quality compressed cellulose sponge sheets requires a thorough understanding of the manufacturing process, a focus on sustainability, and a keen eye for supplier evaluation. By following these guidelines, you can ensure a supply of high-quality, eco-friendly sponge sheets.